When I was recently at the mine and I just had about 1 hour spare time, my friend brought me on the idea to visit the SGS lab. The idea was simple and great, because SGS is a Swiss company and when do you have the chance to get in touch with something Swiss in the bush of Congo? As my skin color is kind of all access card to various buildings, it was easy to enter it and pass the security control. It was like always: “Confident occur in complete ignorance”. However, after stepping in the building, it was asking for the manager and was shown him to his office. After a short introduction of myself (Swiss and chemist) he got very talkative and started to explain in detail what SGS and his lab is doing. It was interesting to listen to him and after a half an hour he offered me to get a tour trough the lab. I could not refuse…

SGS (www.sgs.ch) is the world’s leading inspection, verification, testing and certification company. The company has 1500 labs and about 75’000 employees. SGS says about hisself: “Wherever you are in the world, in whatever industry, you can rely on our international teams of experts to provide you with specialized business solutions to make your business faster, simpler and more efficient. We partner with you to offer independent services that will help you reduce risk, streamline your processes and operate in a more sustainable manner.”

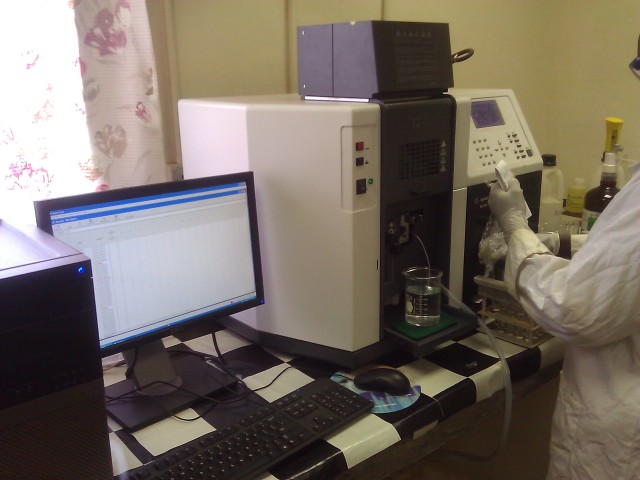

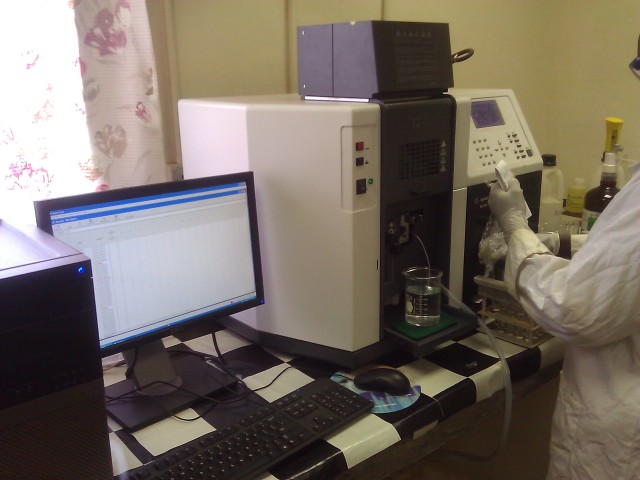

In Kibali Mine, SGS is responsible for testing the samples out of the ground on the gold and silver content by F-AAS (flame atomic absorption spectrophotometry). The process is quite simple and is shown below. By the wa, all the gold which is mined in Kibali goes directly to Switzerland. Interesting…

The to be tested stone and sand sample has to be crushed to a very fine powder (80-90%<75 μm). For that the grey machines are used to crush the stones in rough sand of a few millimeters.

Afterwards the sand has then to be further crashed in a very fine power by the yellow machine.

The sample with litharge (“lead”) and glass fluxes was …

… charged at 850°C (in a crucible) in a muffle furnace and maintained well above 1000°C for 30-40 min until a complete fusion occurred. The lead circulates through the molten mass and collects the precious metal forming Au-Ag-Pb alloy, ….

… which is recovered as a button after cooling and separation from the glassy slag containing base metal and other impurities.

Bone ash and marborite cupel (?) heated to 1000°C are charged with the lead button. This process results in a precious metal bead, …

… which is parted by dissolving in nitric acid. After dissolving in nitric acid, everything except the gold is dissolved. In order to get rid of the “disturbing” silver, the hydrochloric acid is added, which now dissolves the gold (aqua regia), but precipitate the silver as insoluble AgCl. The reagent can then be easily measured by F-AAS for the gold content in a ppb-ppb range.